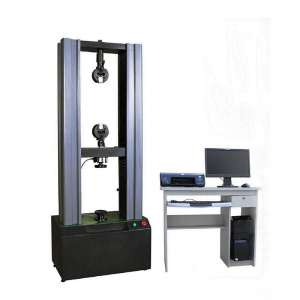

Kugwiritsa ntchito

Makina oyesera a 20kn Computer spring and tester tester / masika amapangidwa ndikupangidwa ndi kampani yathu, yomwe imagwiritsidwa ntchito kwambiri poyesa mphamvu ya mitundu yonse ya akasupe a valve ndi zigawo zotanuka.50kn Computer kasupe kukanika ndi psinjika Tester / kasupe kuyezetsa makina akhoza kuyeza mphamvu ya masika ndi zotanuka chigawo chimodzi pansi mapindikidwe ena kapena kutalika otsala, komanso akhoza kuyeza otsala kutalika kapena mapindikidwe masika ndi zotanuka chigawo chimodzi pansi pa mphamvu zina zoyesera.Makina oyesera amapangidwa ndikupangidwa molingana ndi zofunikira za JB/T7796-2005 Tension and compression spring test test.

Kufotokozera

| Mphamvu yoyeserera kwambiri | 20kn pa |

| Muyezo wa mphamvu yoyesera | 2% ~100% |

| Kulondola kwa muyeso wa mphamvu yoyesera | bwino kuposa ± 0.5% ya mtengo womwe wawonetsedwa |

| Kuthetsa kusamuka | 0.001 mm |

| Kusamuka kwa muyeso wolondola | ± 0.5% |

| Cholakwika chofananira cha mtengo wosinthira | mkati ± 0.5% |

| Kusintha kwakusintha | 0.001 mm |

| Zolakwika zokhudzana ndi mphamvu yowongolera mphamvu | mkati mwa ± 1% ya mtengo wokhazikitsidwa |

| Muyezo wa Crossbeam | 0.001 ~ 200mm / mphindi; |

| Malo okhazikika | 0-600 mm |

| Chipinda chopondereza | 0-600 mm |

| Kuyenda kwakukulu kwa crossbeam | 600 mm |

| Magetsi | 220V 50Hz |

Zofunika Kwambiri

1. Host:Makinawa amatenga khomo lazipinda ziwiri, malo apamwamba amatambasulidwa, ndipo malo otsika amapanikizidwa ndikupindika.Mtengowo umakwezedwa mosadukiza ndikutsitsidwa.Kupatsirana kumatengera lamba wozungulira wa arc synchronous toothed, kufala kwa ma screw pair, kufalikira kokhazikika komanso phokoso lochepa.Dongosolo lothandizira lamba la synchronous toothed deceleration ndi kulondola kwa ball screw pair kumayendetsa mtengo wosunthika wamakina oyesera kuti azindikire kufalikira kopanda mmbuyo.

2. Zida:

Kukonzekera kokhazikika: seti imodzi yomangika zomangika zooneka ngati mphero ndi kuphatikizika.

3. Njira yoyezera ndi kuwongolera magetsi:

(1) Adopt TECO AC servo system ndi servo motor, yokhala ndi magwiridwe antchito okhazikika komanso odalirika, okhala ndi zida zamakono, zochulukirapo, zothamanga kwambiri, zodzaza ndi zida zina zoteteza.

(2) Imakhala ndi ntchito zoteteza monga kuchulukirachulukira, kupitilira apo, ma voliyumu, malire apamwamba ndi otsika komanso kuyimitsa mwadzidzidzi.

(3) Wowongolera omwe adamangidwa amawonetsetsa kuti makina oyesera amatha kukwaniritsa magawo otsekeka ngati mphamvu yoyeserera, kusinthika kwachitsanzo ndi kusuntha kwamitengo, ndipo amatha kukwaniritsa kuyeserera kwa liwiro lokhazikika, kusamutsidwa pafupipafupi, kuthamanga kwa liwiro, kuthamanga kosalekeza. katundu mkombero, Mayesero monga pafupipafupi liwiro deformation kuzungulira.Kusintha kosalala pakati pa mitundu yosiyanasiyana yowongolera.

(4) Pamapeto pa mayeso, mukhoza pamanja kapena basi kubwerera ku malo oyamba a mayeso pa liwiro lalikulu.

+

(6) Dongosolo loyang'anira magetsi limatanthawuza muyezo wapadziko lonse lapansi, womwe umagwirizana ndi muyezo wamagetsi wamakina oyesa dziko, ndipo uli ndi mphamvu zotsutsana ndi zosokoneza, zomwe zimatsimikizira kukhazikika kwa wowongolera komanso kulondola kwa data yoyesera.

(7) Iwo ali mawonekedwe maukonde, amene angathe kuchita kufala deta, kusungirako, mbiri yosindikiza ndi kufala maukonde ndi kusindikiza, ndipo akhoza chikugwirizana ndi LAN mkati kapena maukonde Internet wa ogwira ntchito.

4. Kufotokozera za ntchito zazikulu za mapulogalamu

Pulogalamu yoyezera ndi kuwongolera imagwiritsidwa ntchito pamakina oyesera amagetsi oyendetsedwa ndi ma microcomputer kuti ayese zitsulo zosiyanasiyana komanso zopanda zitsulo (monga mapanelo opangidwa ndi matabwa, ndi zina zotero), ndikumaliza ntchito zosiyanasiyana monga kuyeza nthawi yeniyeni ndikuwonetsa, zenizeni. -Kuwongolera nthawi ndi kukonza kwa data, ndikutulutsa zotsatira molingana ndi miyezo yofananira.

(1) Ulamuliro wogawanika.Ogwira ntchito m'magulu osiyanasiyana ali ndi maulamuliro osiyanasiyana ogwiritsira ntchito, ndipo zomwe zili m'mabuku ogwiritsira ntchito zimakhalanso zosiyana, zomwe zimapangitsa kuti ntchitoyi ikhale yosavuta, yosavuta komanso yachangu kwa ogwira ntchito wamba, komanso kuteteza dongosolo;

(2) Muyezo wanthawi yeniyeni ndikuwonetsa mphamvu yoyesera, mtengo wapamwamba, kusamuka, kusinthika ndi zizindikiro zina;kupeza ndi kuwongolera nthawi yeniyeni pansi pa nsanja za NT monga Win2000 ndi WinXP;ndi nthawi yolondola komanso zitsanzo zothamanga kwambiri;

(3) Chiwonetsero cha nthawi yeniyeni yowonetsera ma curve osiyanasiyana oyesa monga katundu-deformation, katundu-kusamuka, ndi zina zotero, akhoza kusinthidwa ndi kuwonedwa nthawi iliyonse, ndipo ndizosavuta kwambiri kutulutsa ndi kutuluka pamphepete;

(4) Kusungirako makompyuta, kuyika, kutsitsa ndi ntchito zina za magawo oyesera, kusintha kwa zero, kuwerengetsa ndi ntchito zina zonse zimachitika pa pulogalamuyo, ndipo gawo lililonse likhoza kusungidwa ndikusamutsidwa mosavuta, kuti gulu limodzi likhale ndi zida. masensa ambiri.Kusintha kosavuta, ndipo palibe malire pa nambala;

(5) Thandizani njira zosiyanasiyana zowongolera, kuphatikiza kusuntha kwamphamvu kosalekeza kosalekeza komanso kuthamanga kwanthawi zonse, kupsinjika kwanthawi zonse ndi njira zina zowongolera zotsekeka;ndikupereka njira yolumikizira yokhazikika pomwe woyendetsa wapamwamba asintha magawo otsekeka, kuti ogwiritsa ntchito athe kuwona Kutengera kwa gawo lililonse pamayendedwe otsekedwa.

(6) Dongosolo laukadaulo lokhazikitsa mwanzeru njira zowongolera zoyeserera zimaperekedwa kwa ogwiritsa ntchito akatswiri omwe ali ndi mapulogalamu oyendetsedwa ndi pulogalamu.Ogwiritsa ntchito amatha kuphatikiza njira zingapo zowongolera ndikuwongolera kuthamanga malinga ndi zosowa zenizeni ndikuphatikiza mapulogalamu owongolera omwe amagwirizana ndi zosowa zawo.Pulojekiti yoyezera ndi kuwongolera idzawongolera njira yoyeserera malinga ndi zoikamo za ogwiritsa ntchito.

(7) Kusanthula deta pogwiritsa ntchito makompyuta a anthu.Njira yopangira chitsulo imakwaniritsa zofunikira za "GB/T 228-2002 Room Temperature Tensile Test Method for Metallic Materials", yomwe imatha kuwerengera magawo osiyanasiyana ochitira zinthu monga zotanuka modulus, mphamvu zokolola, mphamvu zowonjezera zosalingana, ndi kulowererapo pamanja pakuwunika., Kuwongolera kulondola kwa kusanthula;kukonzanso kwa data kwina kungathenso kuchitidwa molingana ndi miyezo yoperekedwa ndi wogwiritsa ntchito.

(8) Deta yoyeserera imasungidwa m'mafayilo olembedwa kuti athandizire kufunsa kwa ogwiritsa ntchito, ndikugwiritsa ntchito malipoti onse abizinesi ndi pulogalamu yosinthira mawu kuti akonzenso zoyeserera, ndikuthandizira kutumiza deta pa intaneti;

(9) Ikhoza kulemba ndi kusunga ndondomeko ya deta ya ndondomeko yonse yoyesera, ndipo imakhala ndi ntchito yowonetsera kuti izindikire kubereka kwa ma curve.N'zothekanso kupititsa patsogolo ndikufanizira ma curve kuti athandize kusanthula koyerekeza;

(10) Lipoti la mayeso likhoza kusindikizidwa mumtundu wofunidwa ndi wogwiritsa ntchito.Ogwiritsa ntchito amatha kusankha kufotokoza ndi kutulutsa zidziwitso zoyambira, zotsatira zoyeserera ndi zomwe zili pamapindikira paokha kuti akwaniritse zosowa zosiyanasiyana;

(11) Kusintha kwa digito kwa zero ndikuwongolera zokha kwa mphamvu yoyesera ndi kusinthika kumakwaniritsidwa, komwe kumathandizira kugwira ntchito ndikuwongolera kudalirika kwa makinawo.Zosintha zosiyanasiyana zamakina zimasungidwa ngati mafayilo, omwe ndi osavuta kusunga ndikubwezeretsa;

(12) Itha kugwiritsidwa ntchito ku machitidwe osiyanasiyana monga Win98, Win2000, WinXP.Kuwongolera njira zoyeserera, kusintha kwa liwiro la mtengo, kulowetsa magawo ndi ntchito zina zonse zitha kumalizidwa ndi kiyibodi ndi mbewa, yomwe ili yabwino komanso yachangu kugwiritsa ntchito;

(13) Imatha kuzindikira ndikuthandizira kuwongolera kwakunja kwa jog, ndikupangitsa kuti ikhale yabwino kukakamiza chitsanzo;

(14) Ili ndi ntchito yodzimitsa yokha kuti itetezeke mochulukira, ndipo imatha kudziwa ngati chitsanzocho chasweka ndikuzimitsa.

Malinga ndi zosowa zosiyanasiyana za ogwiritsa ntchito, mapulogalamu omwe ali pamwambapa amatha kuonjezedwa kapena kuchepetsedwa kapena kusinthidwa.

5. Mawonekedwe a mapulogalamu ndi mapulogalamu:

(1)Mapulogalamuwa amatha kukhala mu Windows98/2000/XP, ndipo mawonekedwe ake amawonetsa mawindo a Chitchaina/Chingerezi ogwirizana ndi mawonekedwe a Windows.

(2) Njira zingapo zowongolera zitha kusankhidwa kuti ziziwongolera pulogalamu.

(3) Dongosolo lodziwikiratu loyang'aniridwa ndi akatswiri anzeru.Mpaka masitepe 50 akhoza kukonzedwa okha.

(4)Lipoti kusintha

(5) Pali mitundu yambiri ya njira zoyesera, zomwe mungasankhe

(6)Pulogalamuyi ili ndi magawo atatu a oyang'anira, omwe amalowetsedwa ndi mapasiwedi awo, zomwe zimatsimikiziranso kugwiritsa ntchito bwino pulogalamuyo.

Standard

Imakwaniritsa zofunikira za mtundu wa GB/T228.1-2010 "Metal Material Tensile Test Method at Room Temperature", GB/T7314-2005 "Metal Compression Test Method", ndipo ikugwirizana ndi kusanthula kwa data kwa GB, ISO, ASTM. , DIN ndi miyezo ina.Ikhoza kukwaniritsa zofunikira za ogwiritsa ntchito ndi miyezo yoperekedwa.